I have wanted to write something about presses for a while now, and there's so much to talk about them. What are the best brands, ideal format, how important is roller size and the list goes on. I received an e-mail this morning asking about the one problem that everyone seems to have at one time or another as a press owner....rust!

I have wanted to write something about presses for a while now, and there's so much to talk about them. What are the best brands, ideal format, how important is roller size and the list goes on. I received an e-mail this morning asking about the one problem that everyone seems to have at one time or another as a press owner....rust!Rust is a real problem for some of us that live in humid climates. It seems to be insidious, attacking all unpainted surfaces. I've heard all sorts of methods trying to stave it off, but prevention is difficult if you want the press to continue working. The typical printmakers with a rust problem owns an etching press. Lithographers, in general, don't see the problem of rust because it affects the only press roller they have, the lower roller, and it remains unseen for the most part.

On an etching press, the upper roller is right out there where you can't miss it. Rust is pretty easy to spot, and can make a difference in several ways. First of all, it can mess up your blankets - quickly. Secondly, over time, it can attack the roller and leave pits that ultimately could transfer to your image if not corrected.

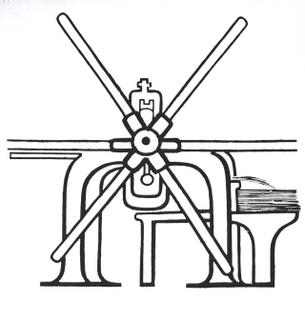

So, what's the best corrective action? Rust begins as a surface problem, and can easily be treated by using a soft wire brush. It is important, however, to note that the upper roller of your press is not smooth! There is some quality designed into the roller surface to allow it to grab the blankets on almost every press. Many rollers are actually lightly threaded, like a large bolt. Others can be sandblasted to give a tooth to the surface. You need to know what your press has so you know how to correct the problem. In general, you want to brush in the direction that the roller turns, not across the surface. You can accomplish this by holding the brush in place and turning the handle on the press....it's slow but effective.

If the rust has become deep-seated, you may want to try buying some Naval Jelly at the hardware store. This is a paint on product that will go after the rust with a vengance. Don't try to oil the roller or spray clear acrylics or enamels to protect it. You might be successful, but more than likely, you'll just decrease the effectiveness of the abrasive surface. Rust is an annoyance, but a little bit of work before it gets bad, and you will be fine.

A final note that has nothing to do with rust. OIL! Presses are very simple pieces of equipment, not high-tech at all. They do need to be oiled on a fairly regular basis. Check with the manufacturer of your press for specifics, but if in doubt, use a 30 weight motor oil on the bearings, and a little grease on the pressure screws maybe once a month to be safe. Usually, gear boxes need little or no attention in this respect, but check with the maker to be sure.